COIRE GLAS PUMPED HYDRO STORAGE SCHEME

The Coire Glas Pumped Hydro Scheme is a 1296 MW pumped storage project in the Scottish Highlands situated on Loch Lochy. The client, SSE Renewables, engaged Stantec as the owner’s engineer to develop a reference design for tendering. It is the first large-scale pumped storage scheme to be developed in the UK for more than 30 years and will more than double the United Kingdom’s existing electricity storage capacity.

The scheme is proposed for a greenfield site using Loch Lochy as a lower reservoir and constructing a new reservoir within the cradle of a valley amongst the neighbouring mountains, with a significant difference in elevation between the two reservoirs. Underground tunnels and pipelines connect the two reservoirs via an underground power station to allow pumping of water uphill and then energy generation from the downhill flow of water.

The system acts as a battery taking surplus energy from the grid from other renewables and pumping water to the higher reservoir. Then in times of energy demand, energy is generated as a typical hydropower plant with water flowing from the upper to the lower reservoir.

Stantec’s involvement covered all design aspects of the scheme including the powerhouse complex, hydromechanical machinery, electrical plant, the upper reservoir, spillway, inlets, outlets and surrounding roads.

My involvement was focused on the management of spoil, hydraulics and flooding. This included the following:

• Developed a spoil management model for assessing production rates, storage, reuse and transport of excavated material throughout the project based on the construction programme.

• Designed diversion culvert and bottom outlet for upper reservoir.

• Completed flood study of upper reservoir.

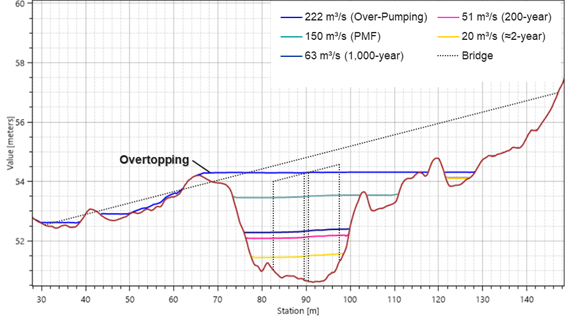

• Performed hydraulic modelling of the river downstream of the upper reservoir in HEC-RAS to determine tailwater at dam and inundation of surrounding area in event of emergency failure.

• Assessed hydraulic performance of three bridge structures along main access road to the site.

• Supported the review of tender submissions, focusing on the Spoil Management Plans.

My primary task was working on spoil management and developing a tool for modelling production, storage, demand and supply. I found this task particularly engaging for two reasons: I was given sole responsibility to manage this independently and the problem had no clear solution or method for solving. I had the freedom to find my own method of solving it.

I developed an Excel spreadsheet using Visual Basic that modelled production rates based on construction activities. The inputs were dynamic, which allowed for tailoring the construction schedule and storage methods to optimise the management of rock spoil. The technical side of the problem became more interesting as solving it required a creative approach.